With UK bakeries under pressure to streamline their processes while keeping their costs in check, a technology to help with product development could prove to be one easy solution

The UK’s baking industry has faced numerous challenges in the past few years and none more so than in 2024.

From poor weather affecting the UK wheat harvest to price rises in components such as yeast and salt, according to a recent report, the pressure is on for bakeries to save money wherever they can while retaining consumer interest in a market where prices once again threaten to rise. Yet with 99.8% of British households buying bread and 11 million loaves consumed each day [UK flour millers.org], the category is a staple and, in order to stay profitable, bakeries increasingly need to find solutions to streamline their operations, manage their costs and deliver products that will win over consumers time and again – and ones for which they are prepared to pay.

To achieve this, there is an increased need to improve production efficiency and make savings on both ingredients and energy, as well as reducing the waste associated with bread production.

Indeed, waste is a major issue in the UK’s bread market. According to a report by Waste Managed, bread is one of the most commonly wasted food items in the UK, with approximately 900,000 tonnes wasted each year, both at production and consumer levels. Yet extending the shelf life of loaves can benefit the industry in a number of ways:

● retailers have more time to sell the bread as it stays fresh on-shelf for longer;

● it can help reduce costs in supply chains as it allows for more efficient packing and delivery;

● and the reduction in waste can be substantial – in fact, one study recently identified that increasing the shelf life of bread by one day, equivalent to a 20% shelf-life extension, the volume of waste could be reduced by 62 kg/day, based on a total daily production of 1000 kg of bread and assuming no knowledge of the specific amount of waste generated across the different stages of the supply chain.

So, bakers would be well-advised to explore all avenues at their disposal to reduce waste and streamline their process efficiency.

How micro-encapsulation can help

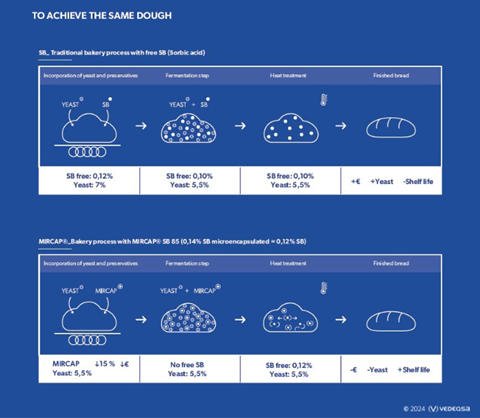

One technology that has seen its use steadily increase in bakery around the world is the process of micro-encapsulation. In bread, two of the most common preservatives used are calcium proprionate and sorbic acid, protecting the bread against yeast and mould growth. However, during the kneading and developing processes, they can interact with the yeast, leading to the bread not rising as it should.

Micro-encapsulation of both acids controls their release, enabling it to take place beyond the kneading and fermentation stage when a certain temperature is achieved, thus improving the performance of the dough, increasing the quality of the finished bread and extending its shelf life.

One specialist in manufacturing additives for the food industry, Vedeqsa, based in Spain, has become expert in food micro-encapsulation and is selling the technology to major bakeries across Europe and in the Americas. The company’s registered trademark MIRCAP® enables bakers to control the leavening process to achieve optimal dough expansion and produce baked goods with the desired texture, volume and flavour, says Borja del Real, technical delegate at Vedeqsa.

“We’ve been working with the baking industry for around eight years,” he says. “Even just a low amount of calcium proprionate interacts with the yeast and you can have a situation where you have add more yeast and spend more time developing the product. Then, you can have additional problems with the dough as it can become more sticky.

“With the calcium proprionate micro-encapsulated, you avoid these problems. What’s more if you increase the amount of micro-encapsulated calcium proprionate to its maximum limit – which I believe is now 3g per kg, you can obtain a shelf life of 15-16 days in breads without them getting mould. Then, if you use both micro-encapsulated calcium proprionate and micro-encapsulated sorbic acid, the shelf life can be extended to one month.”

The toughest challenge, he says, is convincing bakeries that this is a game-changer for them and for their customers. “It’s very easy to demonstrate,” he says. “All you are doing is changing the calcium proprionate for the micro-encapsulated version at the same level. You get fermentation for less time – or an even more reduced time if wished. It’s about controlling the process.”

Vedeqsa is already producing more than 2,000 tonnes of micro-encapsulated sorbic acid for the wider food industry and more than 1,000 tonnes of micro-encapsulated calcium proprionate. The company works with a wide variety of bakeries from large to small.

Using Vedeqsa’s process, yeast consumption can be reduced by 15-20% while achieving the same desired loaf volume, thus saving money, while the kneading and fermenting processes are simplified, shortening the production time.

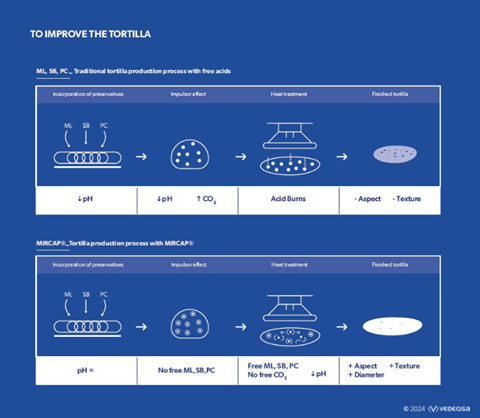

And it’s not just in bread that micro-encapsulation can be used. In tortillas, for example, preservatives play a major role in the hot-pressing and baking processes to deliver the product’s texture, flavour and shelf-life, with the acids used to lower the pH or the product and maximise the efficacy of preservatives under acidic conditions.

MIRCAP® permits the release of the active ingredient to occur only during the hot-pressing and baking processes, preventing premature carbon dioxide gas release that can lead to an uneven rise and overly puffy texture in the end-product, reveals del Real. The result, he says, include increased fluffiness, thickness and roundness of the tortillas and extended shelf life due to optimised use of the preservatives.

Vedeqsa, based in Terrassa in Spain, has technical staff on hand to guide bakers through the process of changing to the micro-encapsulated format and can help them trial the products at their own facilities.

While micro-encapsulation is not a brand new technology, its use in the UK baking industry is not yet widespread [check]. Yet there are plenty of scientific studies to show that its use can enrich and fortify bakery, pasta and cereal-based products.

Del Real puts it succinctly: “If bakers who are using regular calcium proprionate change it to micro-encapsulated calcium proprionate, they are going to save time and they are going to save money. What’s more, they don’t even have to change the labelling on their products because in effect, it’s the same ingredient, just in a different form.”

Vedeqsa’s MIRCAP® micro-encapsulated calcium proprionate and micro-encapsulated sorbic acid are available to UK bakers through its exclusive distributor Ingredients UK. To find out more, please visit the website on www.ingredients-uk.com or email the company’s sales department on sales@ingredients-uk.com .