Meeting manufacturer and retailer sustainability targets presents a huge opportunity for bakers. But after renewable energy, where can they look next for opportunities that can really benefit carbon output and nutrition?

Sustainability targets present a huge opportunity to combat the carbon impact of the baking industry. Most major UK retailers aim to become carbon-neutral by 2035, with many internal corporate social responsibility (CSR) programmes aiming to meet that deadline sooner. With food contributing to 11% of greenhouse gas emissions in the UK1, the bakery producers of today are embracing changes to meet these lofty goals.

According to a British Baker article in early 20232, “Baker & Baker has switched to 100% renewable electricity at its UK sites and has started a project to fully map its European carbon footprint and develop a strategy to achieve net zero.” Renewable energy is often the first port of call when reducing carbon outputs across manufacturing, but once those initiatives are underway, where can operators look next to reduce their carbon footprint?

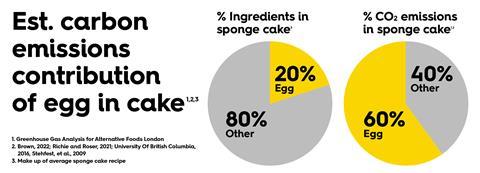

Eggs are the largest contributor to C02e in baking

Recent research by plant-based egg alternative supplier Oggs found that, on average, a sponge cake recipe contains around 20% egg raw ingredient, yet around 60% of the carbon emissions from that cake are caused by the egg3 component.

“That over-index in the environmental impact of egg in cake is one of the main factors prompting retailers and foodservice operatives to explore alternative options,” says Hannah Carter, founder and CEO of Oggs.

In principle, finding a lower carbon alternative seems like a good idea, but egg plays an important functional role in creating and maintaining structure as, without that egg, cakes and bakes can become dry and dense. Finding an egg alternative that supports sustainability (and health) targets, functions effectively and avoids adding a complex list of ingredients, seems almost impossible.

Stability of supply and availability

According to a recent article in British Baker4, “the egg industry has been dealing with ‘unprecedented’ pressures, according to trade body The British Egg Industry Council. Soaring costs have caused many egg farmers to cease production rather than face the risk of losing money on the eggs they produce, while avian influenza has added to the strain on producers.”

The current egg crisis is yet another factor prompting bakery manufacturers to consider egg alternatives that, unlike eggs, have stable costs and supply chain. With egg availability and pricing uncertain, and as more and more farmers leave the industry, a proactive switch to an egg alternative is a way to future-proof operations, while benefiting from the sustainability and nutritional benefits.

It is a perfect storm of supply issues and dramatically rising costs (which are predicted to continue through 2023), coupled with the need to meet sustainability targets, that makes reducing reliance on eggs for retailers and their suppliers an obvious step.

What are plant-based egg alternatives?

Aquafaba is the name for a mixture of chickpea extract and water – the liquid contains proteins and starches that perform as an egg does across a range of baking applications. A relatively recent discovery, it wasn’t until the mid-2010s that bakers started using this magic liquid in recipes that would have traditionally used eggs5.

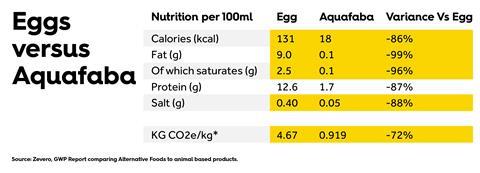

While the sustainability credentials of aquafaba are an initial benefit, it’s in health and nutrition where the product truly shines. Aquafaba produced by Oggs has 86% fewer calories than egg gram for gram, as well as 96% less saturated fat and 88% less salt6. These reductions have a big impact when it comes to creating HFSS-compliant products that still taste delicious.

Not just an alternative – a better option

Replacing egg with plant-based alternatives doesn’t just help meet health and sustainability benefits; it creates better bakes. In trials by Oggs, leading supermarket category directors and product developers preferred the cakes containing aquafaba. Sponge cakes were described as ‘lighter’ and were noted to have ‘more flavour’.

Following in the footsteps of a Tesco initiative which started with a part beef/part veg blend of mince, to provide healthier and more sustainable products, these nudge tactics are spilling over into the bakery world. Retailers and foodservice operators are asking bakery manufacturers to explore both removal of egg and part egg/part plant egg blends, with products like aquafaba being the first port of call.

Aside from customer and consumer benefits, there are process and factory gains to be had too. The ambient storage and transport of liquid egg alternatives provide considerable advantages over egg. With a shelf life of up to one year, plant-based egg alternatives also mean that waste can be kept to a minimum, and stock can be on-hand in case orders unexpectedly increase.

“Creating an egg alternative which is simple to use, that does not compromise on product quality and contributes to HFSS targets is critical; we designed our product with large-scale bakeries in mind,” says Carter.

Swap eggs for Oggs Aquafaba

Oggs is a great solution to current needs across the baking industry, with aquafaba available in 10L and 1000L pallecon formats.

Whether in egg reduction or total egg replacement strategies, Oggs’ manufacturing and food science teams are available to support across both supply and process to successfully swap eggs for plant-based alternatives.

To get in touch with Oggs and explore how their experts can help meet baking needs, click here.

Sources

1 BBC, Climate change: Is the UK on track to meet its targets?

2 British Baker, https://bakeryinfo.co.uk/finance/sustainability-what-are-the-baking-industry-priorities-in-2023/675572.article

3 Brown, 2022; Riche and Roase, 2021; University of British Columbia, 2016, Stehfest, et al., 2009

4 British Baker – Have ingredient suppliers cracked the egg supply problem?

5 Epicurious, Chickpeas – An Explanation and a History

6 Zevero, Greenhouse Gas Analysis for Alternative Foods London