Bakeries have spent the last year navigating national lockdowns and continuous changes to their business, finding themselves having to switch up their products, manufacturing processes and reviewing costs. Multivac investigates ways in which they can successfully ride the waves of change.

Shop closures, lockdown restrictions and staff redundancies are just some of the topics seen daily in the bakery sector and, unfortunately, the challenges that Brexit is still likely to bring cannot be ignored.

So how can the bakery sector master these modern challenges at all levels?

Introducing intelligent, automated manufacturing solutions can make a major difference to businesses of all sizes by designing efficient, hygienic and cost-effective production processes, regardless of budget.

Automated manufacturing processes tend to conjure up thoughts of large, high-speed production lines with numerous robots and very little human intervention and while this is still part of what automation has to offer, it is not the only way in which bakeries can look to automate their production for increased efficiency.

Bakeries can introduce a single machine or a system of machines linked together to perform repetitive tasks quickly, as well as help operators perform the same tasks at a higher frequency – for example introducing conveyor systems between workstations to increase the flow of products from one place to another or helping to prevent human injury. Meanwhile the labour savings realised with the introduction of more automated or streamlined processes will enable that valuable resource to be utilised elsewhere in the bakery.

Automation can be implemented at any stage of production, you’re never too small to save big.

Bakeries have many options to consider when it comes to introducing automation to the production process, and the range of equipment available on the market today is as wide-ranging and diverse as the different products these machines help to make.

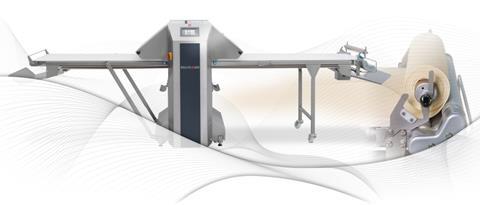

A small business’ first step into automation could be a reversible dough sheeter, for example. Designed to replace the hard work of creating a dough or pastry sheet manually, dough sheeters can offer bakeries very gentle dough handling for excellent quality, accuracy and yield. This can help any bakery looking to increase efficiency, but is also a future-proof investment.

Take one of the nation’s favourite bakery snacks, the humble sausage roll, for example . While it is a long and usually difficult process for a baker to create a dough sheet manually, it is also very time-consuming to construct a consistent finished product by hand; it has to be measured, filled, folded and crimped. In this instance, a baker could only produce around 600 products per hour at best from a pre-prepared laminated dough sheet.

However, side-seal automation can allow the production of four sausage rolls in a row at a rate of 24,000 per hour, on a line just 8.3 metres long.

Moreover, in some cases, these products have to be placed on a tray manually, but if there is space to add a traying-up unit, then it is possible to further automate the transfer of finished products onto a tray at a rate of six trays per minute.

Where there is a need to automate pastry make-up where space is at a premium, then compact equipment design can help small and medium-sized bakeries produce a variety of bakery products; cut, folded, coiled, filled or punched – the possibilities are endless.

Folded D-shape products and coiled products, such as cinnamon swirls, can also be produced on such a line, with product changeovers quick and simple, and no tools are required to change tooling from one product to another.

The challenge is to create unique-looking products that stand out on the supermarket shelves or in a shop’s front counter. This requires bakers to construct bakery products from a dough sheet that is both accurate in thickness and width, providing precise product weight and therefore improved yield.

Meanwhile, when it comes to large, high-speed production lines, if increased capacity is the requirement, for example from one tonne up to nine tonnes per hour, then a fully automated line instead of single machines will be more suited to a bakery’s goals. In this instance, a fully automated laminating line can provide continuously laminated pastry onto a makeup line.

However, industrial lines need to maintain the sensitive structure of the dough throughout the whole production process so an extremely gentle working method can ensure the finest product quality.

When it comes to automation and mastering these modern bakery challenges, Fritsch and Multivac can help bakeries to introduce automated or streamlined processes to any sized business, allowing them to save on labour and repurpose and utilise this valuable resource elsewhere in the bakery, while also increasing efficiency:

For more details on how Fritsch can help automate your baking processes, visit the website here or contact the company on sales@multivac.co.uk or 01793 425800.