It’s been a dynamic year for many bakery businesses in the UK, with sizeable sums invested to capitalise on growth opportunities.

From new production lines and sites, to crowdfunding successes and even an environmentally-friendly fleet, we glance back at the biggest and smartest investments of 2023:

Jones Village Bakery goes flat out with pancake line

Back in February, the Wrexham-based manufacturer saw its new £2m pancake line – described as one of the world’s biggest – come online right in time for Shrove Tuesday.

At 20m long and 3m wide, the line is capable of producing 34,000 units an hour, which can range from a small Scotch pancake to a large US-style buttermilk pancake.

According to MD Robin Jones, the creativity and innovation of Jones Village Bakery’s NPD team had helped drive demand for pancakes in the UK and across Europe. “The reason we have bought this new production line is quite simply that our pancakes are literally selling like hot cakes,” he added.

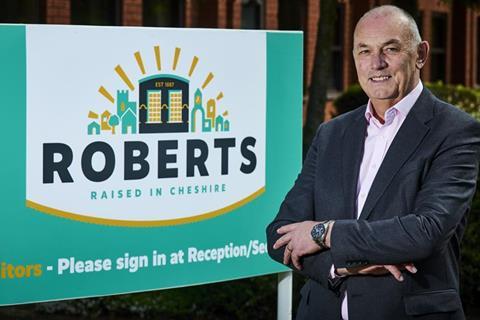

Roberts Bakery shakes up its centres

Similar to Jones Village’s phoenix-like rise from the ashes in recent years, Roberts Bakery is looking to recover from a massive fire at its Northwich site by enacting its ‘most important operational overhaul in decades’.

This includes the creation of three separate ‘Centres of Excellence’ for biscuits, bread, and specialty breads respectively. Production of its Little Treats biscuit range is to be relocated four miles down the road in the Cheshire town of Winsford. There would be improvements made to the operational layout of its bread-making plant at Northwich, while its Ilkeston site in Derbyshire would continue to focus on artisan and specialised bread products.

“This is a significant investment plan which will allow us to rebuild and revitalise the company and make sure it is fit for the future,” Roberts managing director Bill Thurston said.

Cavan Bakery ramps up with new site

A move into a purpose-built 15,000 sq ft factory in Walton-on-Thames earlier this year is aimed at helping Cavan achieve an ambitious target of doubling its turnover to £10m by the end of next year. The new bakery is three times the size of its previous production site, and also came with an investment in new machinery to help reduce running costs and improve efficiency.

British Baker sat down with owner and CEO Jeff Greenall and MD Nicky Taylor to discover more about the craft bakery’s expansion plans including a shift to viennoiserie and adding new shops and wholesale customers.

Genius thinking expansion through £7.5m loan

The gluten-free specialist secured a £7.5m asset-based loan from financial services company Shawcross in April to improve efficiency and product lines at its Bathgate bakery, and also expand its UK and European presence. This followed on from its acquisition by German confectionery group Katjes Greenfood last year.

The brand has since been busy rolling out recipe updates to product ranges including most recently to its sliced wrapped loaves, now billed as its “best ever bread”.

Supporting this launch is a £500,000 advertising campaign, which Genius said will highlight its “quest to bridge the gap between mainstream and gluten free taste and quality”.

Srsly Low Carb gets lift from £500k loan

Half a million in funding from the East of England Regional Loan Scheme back in April was to be used by Srsly Low Carb to support ongoing product and packaging development, enhance sales and marketing initiatives, and recruit new staff.

The keto-friendly brand, which operates a production site in Hemel Hempstead, has enjoyed significant growth and achievements over the past 12 months including revamping its brand identity; extending its reach into jams, condiments and ready meals; becoming an approved NHS supplier; and securing an exclusivity agreement with US supermarket supplier Gourmet Foods International.

Last month, it sailed over its crowdfunding target by more than a third, attracting an investment total of £274,197 pledged by 331 backers.

Incredo sweetened by £24m development deal

A whopping $30m (£24.2m) in funding was provided to global food tech company Incredo in May to help it develop new products using its first-of-its-kind, clean label sugar reduction ingredient.

Suitable for baked goods and confectionery, Incredo Sugar is said to contain 40% fewer calories than regular sugar without compromising taste, mouthfeel, or texture. It’s made by binding cane or beet sugar with trace amounts of a natural carrier to aid in the delivery of sugar molecules to sweet taste receptors on the tongue.

Not only can the ingredient solution help fight obesity, notes Incredo, it can also provide sustainability benefits by reducing the environmental impact of the sugar industry.

Project D smashes crowdfunding target

Having seen its mastery of TikTok yield sweet success, the Derby-based doughnut specialist brightened up its balance sheet over the summer with a crowdfunding campaign that raised £524k from 849 investors against a £400k target.

This has allowed Project D to start expanding into brick and mortar retail, with its flagship store opened in York city centre in October and stores in Sheffield and Nottingham following.

Product innovation, digital marketing, e-commerce, and new hires are also among Project D’s priorities to be turbocharged by the investment, while plans for a doughnut festival next year – affectionately dubbed Glaze-tonbury – has been unveiled too.

Guenther Bakeries starts rolling out the buns

The international bakery firm unveiled the latest extension of its long-term partnership to supply McDonald’s, bringing its new £38m factory at Lyon Park in Coventry online in September.

Utilising cutting-edge technology, the site is capable of baking around 1.1 million buns per day for the fast-food giant’s burgers across the UK.

It is also to create up to 90 new jobs for people (85% of which have already been recruited from the local area), with the potential for future new roles to emerge in the future.

Pladis invests £2m to store bulked up Carlisle production

The snack manufacturer swung open the doors of its new £2m warehouse in August, which supports expansion of its Carlisle production site.

With space for 1,600 pallets, the warehouse has also generated 50 new jobs in the Carlisle team, said to be “an important part of the global Pladis family”.

Carr’s Table Water Biscuits, Flatbreads, and Savoury Assortments, McVitie’s Ginger Nuts and Gold Bars, and Go Ahead Fruit & Oat Bakes are among the products made there.

Wrights cleans up with gas-powered fleet

Bakery supplier Wrights spent £1.3m on a new fleet of eight vehicles fuelled with compressed natural gas in April.

Used to help distribute its range of sweet and savoury goods baked at its Crewe site to foodservice and retail customers across the North West, the vehicles are expected to bring a 95% saving in carbon emissions.

“We are working hard to get ahead of the government-set target of reducing carbon emissions by 2030,” said the group’s health, safety and environmental compliance manager Paul Strangwood.

CherryTree Bakery to rise sales with site expansion

The acquisition of a 12,000 sq ft building next to its Burnley headquarters in March has the tray bake specialist setting its sights on doubling turnover in the next three years to £50m.

CherryTree said the £1m expansion, which came after securing new contracts with national retailers, would enable it to meet the additional demand and strike deals in new markets.

It ran a recruitment drive for 50 new staff, introduced a new weekend shift and launched a new production line earlier in the year.

Bakery in review 2023

British Baker looks back at the highlights of the baking industry in 2023, from the big investments and acquisitions to top launches, and new faces leading the charge

- 1

Currently

reading

Currently

reading

Raising some dough: the biggest investments of 2023

- 3

- 4

- 5

- 6

No comments yet