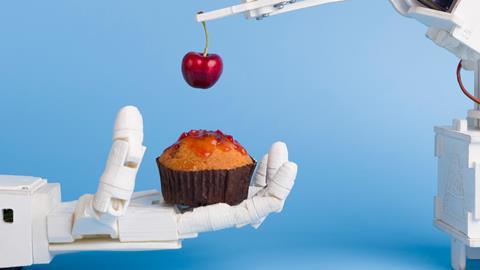

To automate or not automate – that is the question (in the cake decorating world at least). To debate this, we hear from two industry experts on the pros and cons of automation when it comes to creating beautiful sweet treats.

Sonia Bal, director of marketing at Unifiller

“Anything from mid-filling with buttercream or fruit filling, or syrup spraying layers, to top and side icing, to bordering, to writing can be automated.

Robotics can allow for customised intricate writing and drawing on cakes, while machines like enrobers and drizzlers can enrobe cakes with chocolate. Even cheesecake patterns can be customized through the tooling used to swirl the pattern into cheesecakes. Sprinkling machines can also be used to sprinkle cakes and cupcakes with confetti.

Perhaps what still requires the hand touch is the placement of delicate or intricate toppings like fruit slices, nuts, or shaved chocolate. Equipment may be too rough in handling the placement of delicate decorations on cakes.

Cake decorating equipment can save cake producers significant time and effort, increasing yield and reducing the injuries that can often come from repeatedly squeezing a pastry bag for decorating cakes. It is especially ideal for cake producers who sell large quantities of specific skus and need cakes to look consistent for branding purposes.

For example, one of our customers were able to process upwards of four times their current output. The Unifiller Cake-O-Matic (COM) allowed them to reduce personnel and provide consistent weights, appearance, and rates. They were also able to utilise less skilled staff to complete high-quality products, which was a lifesaver in times when it was hard to recruit staff for their bakery.

Depositors like the COM can deposit accurate batter portions pre-bake and can be converted easily into a cake decorating system. We also offer equipment that can fully cover a cake with shells or swirls, or bordering systems. Our systems include those that can decorate round cakes, sheet cakes, bar cakes, and cupcakes.

For a small cake decoration business, something as simple as our entry-level depositor, which is portable and compact, can be used to accurately portion batter deposits, ensuring reduced product waste that helps control ingredients management, while also fitted with attachments to decorate, inject etc.”

Richard Fowler, head of Sponge.co.uk

“The ability to fully automate all aspects of cake making is already there and is now being used by many large-scale producers. The question is – do consumers want this?

Since starting Sponge.co.uk in 2009, we believe that cakes should be decorated with love, and that this is made possible only by hand.

Despite our significant growth since then, we still consider the hand-decorating process a priority, which is why we keep the automated processes to a minimum when it comes to cake decoration.

The only step in the decorating process that is automated is when a ‘splodge’ of buttercream is added into the middle of a cake, ensuring the exact measurement is given to each cake. Once this is complete, the buttercream is then spread carefully by hand and the remaining decorating finished by hand too.

For some of our cakes, such as the popular pinata cake, we use an enrober to add the buttercream. The enrober works by carefully layering the buttercream around the outside of the cake. The buttercream is then tidied up and finished by hand, before our cake decorators carefully add the chocolate curls.

Most of the decorating process could be automated, however we feel where possible this should be avoided. When customers pay for our cakes to be delivered across the country, it is only right that it should be made with love and care, which we feel would be difficult to achieve if using automated equipment.

If a customer desires a large recurring batch of products that look mostly identical, then an automated decorated process might be preferred. However, if the customer wants a personalised, tailor-made cake with maximum flavour and particular decoration, then the human touch should be the priority when choosing where and what to purchase.

We’re now experiencing hundreds of orders per day, peaking during key seasonal events. Despite this, we have no plans to further automate our cake making process. We feel it would be unfair to our repeated and loyal customers, who come to us for quality personalised cakes, for our team to begin automating the decorating process. We’re traditionalists in that we feel cakes deserve a personalised touch, and this is embedded in our ethos and company culture.”

No comments yet