Digitising supply chain traceability is crucial in today’s modern bakery industry, as outdated paper systems simply don’t cut it anymore. Here, Mountain Stream offers a five-step solution to show how simple and effortless traceability can be when the right systems are adopted and used.

For many organisations, managing supply chain traceability remains a time-consuming, complex, and often fragmented process, leaving room for errors that can disrupt production, fail health & safety inspections and damage reputation. However, in today’s demanding food and drink industry, traceability is evolving from a compliance requirement into a core pillar of responsible and efficient business operations. So how can bakery businesses keep ahead of the game?

Regulatory compliance and risk management: the basics

Governments and regulatory bodies are increasingly mandating traceability, requiring companies to document product origins and materials with precision.

Non-compliance can lead to heavy fines, product recalls, or even legal action. More importantly, traceability enables organisations to respond swiftly when issues arise – isolating affected batches, identifying suppliers responsible, and mitigating risks before they escalate into crises.

In the UK, according to the Food Standards Agency, as a Food Business Operator (FBO), you are responsible for the safety of the food which you produce, distribute, store or sell.

You must:

● Not place unsafe food on the market (food is unsafe if it is injurious to health or unfit for human consumption);

● Comply with food law in the production, distribution, storage and sale of food;

● Be able to trace suppliers of your food and the business customers that you have supplied;

● Remove unsafe food from the market in the event of a food safety incident;

Software solutions are helping companies comply with these standards automatically, maintaining digital records that regulators can audit. As compliance expectations evolve – particularly around allergens, labelling, and sustainability – digital traceability tools are becoming indispensable.

Why managing traceability is so difficult

Many businesses struggle with traceability, due to the complexity and the fragmentation of data. They still use manual processes, relying on spreadsheets, PDFs, and emails to exchange supply chain data – prone to human error and nearly impossible to audit efficiently.

Small and medium-sized enterprises (SMEs) may think they lack the resources to implement sophisticated digital systems, even though they’re part of larger supply chains that demand transparency.

These challenges make supply chain traceability feel cumbersome, but with the right approach, bakery businesses can transform it into a manageable – and even strategic – capability.

Supply chain traceability – at a glance

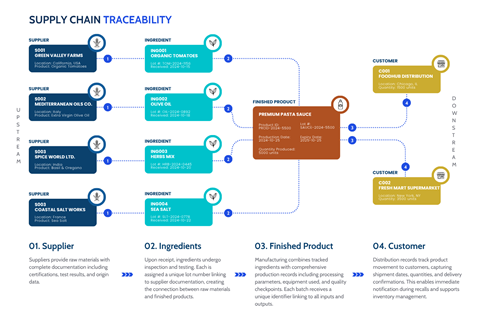

Supply chain traceability refers to the ability to track the movement of products, ingredients, and materials throughout every stage of the supply chain — from raw material sourcing to the end-consumer. In the food and beverage industry, it allows companies to know where every ingredient came from, how it was processed, where it went next and recalling quickly and efficiently.

There are two key aspects:

1. Tracking – following a product’s path downstream through the supply chain (from supplier to consumer).

2. Tracing – moving upstream to identify the origins and history of a product (from consumer back to source).

Five steps to build and manage effective supply chain traceability

1. Track ingredients from the moment they arrive

The best traceability begins at the door. Every delivery – from flour to fillings – should be logged with a batch or lot number as soon as it enters the facility.

Simple barcode printing and scanning eliminate manual entries.

Think of it as creating a digital ’paper trail’ that follows each ingredient throughout its life cycle – transparent, accurate, and instantly searchable.

2. Connect production and inventory data

One of the most common challenges businesses face is disconnected systems – production schedules in one spreadsheet, stock lists in another. When data isn’t synchronised, it’s nearly impossible to track how raw ingredients move through production and into finished goods.

An integrated system allows teams to work from the same real-time data – ensuring that what’s made, packed, and shipped always matches what’s recorded.

3. Audit, monitor, and improve continuously

With a robust traceability set-up in place, isolating affected lots can take minutes rather than hours. That speed minimises waste, protects relationships, and shows regulators that a business’s processes are under control.

Once a traceability system is in place, it’s essential to maintain it actively. Conduct regular audits to ensure data integrity and identify gaps.

Traceability is not a one-time project – it’s an ongoing process of refinement. As regulations evolve and technology advances, systems should adapt accordingly.

4. Use data to strengthen compliance and audits

Audits often bring anxiety, especially when records are scattered across binders and clipboards. Digitising traceability process simplifies everything – every transaction, from receiving to delivery, can be stored and retrieved in seconds.

Modern tools also make it easier to meet HACCP and FSA traceability standards. Instead of treating compliance as a chore, businesses can turn it into an advantage: a proof point that operations are disciplined, transparent and reliable.

5. Build a culture of traceability

Technology alone cannot deliver full traceability – it depends on people. Training staff to record lot numbers, follow production logs, and report discrepancies consistently is key.

When everyone understands how traceability safeguards both product quality and brand reputation, compliance becomes second nature. Sharing data openly across departments – from procurement to logistics – fosters accountability and pride in getting it right.

The food safety factor

Food safety is the most immediate reason for adopting traceability systems. Contaminations – whether biological, chemical, or physical – can occur at any point in production or distribution. When an outbreak or contamination event happens, the speed and precision of the response determine how effectively it can be contained.

Without robust traceability, recalls can become chaotic and expensive, affecting entire product lines and damaging brand reputation. With end-to-end data visibility, companies can pinpoint the affected batches, identify the source of contamination, and remove only the compromised products. The result is faster recall execution, minimised losses, and better protection of public health.

Bonus: Digital tools are making traceability easier

Digital transformation is the key to simplifying traceability. A simple cloud-based platform centralises data, making it accessible and auditable.

Platforms like Streamline by Mountain Stream combine lot tracking, inventory control, and automated reporting in one interface, helping bakeries achieve traceability while saving time and streamlining processes across the board.

Mobile interfaces allow field workers, inspectors, or distributors to input or verify data on-the-go, closing gaps that traditionally plagued paper-based systems.

Discover Streamline’s Lot Tracking and Traceability Feature.