Bread is one of the worst culprits for food waste in the UK – both from a manufacturing and consumer standpoint. Yet marginal gains can contribute significantly to bakery waste reduction, thereby saving costs and improving sustainability credentials, argues Lesaffre UK & Ireland

With more than 100m tonnes of bread baked every year, it’s estimated that about 900,000 tonnes go to waste, according to an article by businesswaste.co.uk. It points to overproduction, spoilage and improper storage as key reasons behind bakery waste and notes that “the more rubbish your bakery produces, the higher your waste disposal costs”. In fact, bread is considered to be one of the most commonly wasted food items in the UK – both at manufacturing and consumer level.

Yet there are plenty of actions bakeries can take to minimise waste, thereby saving considerable costs and improving overall sustainability – as bakery waste, along with other food organic matter, produces methane which contributes to global warming.

Almost half of all edible food surplus comes from bakeries, according to Waste Managed, and bakeries could prevent up to 75,000 tonnes of edible food waste every year, it says. Conventional methods of reducing waste in a bakery include a waste audit to identify the level of waste and target problem areas, assessing customer spending habits to optimise inventory management and donating unsold products to local charities or food banks.

Taken as a whole, however, tackling issues such as waste management can seem an insurmountable problem, but if approached in a tactical fashion, this need not be the case, as even small individual steps can add up to a superlative result.

The big impact of marginal gains

In fact, the concept of taking small steps or making marginal gains, highlighted in a BBC News article from a decade ago, illustrates how these can lead to a marked effect when added together. Although, in this instance, the article referred to the approach to winning sports races, engendered by former British Cycling performance director Sir David Brailsford, the concept can be applied in businesses of any kind. Brailsford referred to the possibility of making a 1% improvement across a range of areas, which, cumulatively, could add up to significant improvement. This starts with identifying weaknesses and, instead of considering them a threat, look at them as an opportunity to move forwards. Indeed, according to the report, this marginal gains approach has been adopted by many of the most innovative companies, including Google, which found that tweaking the shade of its toolbar from a darker to a lighter blue increased the number of click-throughs, thereby increasing revenue dramatically.

Streamlining bakery production

Beyond the more conventional methods of handling waste cited above, streamlining production processes can also feed into saving costs, waste reduction success and improved sustainability. One marginal gain bakeries could make would be to maintain dough stability during the production process, even during unexpected interruptions, says Jorge Semiao, marketer at ingredients company Lesaffre UK & Ireland.

While refrigeration and freezing have typically been the go-to solutions for controlling fermentation and ensuring dough stability, this can involve significant investment in equipment, higher energy costs and higher CO2 emissions, he notes. As a result, the company has developed T-Control 10.25 Yeast and T-Control 10.25 Improver. The specialised yeast is designed to control fermentation and prevent dough from over-developing, while the improver strengthens the dough’s gluten network and supports fermentation control to be able to deliver stable, processable dough. This results in a highly tolerant dough that maintains its volume and structure for several hours until the dough is ready to bake without requiring cold storage, resulting in reduced energy consumption with a subsequent reduction in costs and a lower carbon footprint.

In turn, each of these elements enables bakeries to adjust production schedules and reduce potential waste as the dough remains stable and processable, thus eliminating the need for costly rework or a discard.

Yeast and improver trials: the results

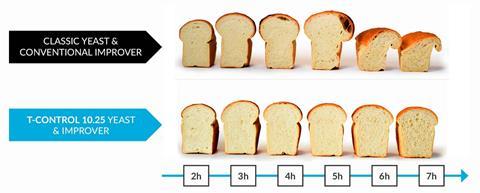

Trials with the T-Control 10.25 system (using the Chorleywood Bread Process) compared to standard high-active yeast revealed that, after six hours’ fermentation at 25ºC, the T-Control 10.25 yeast and improver produced a stable well-structured dough, while the classic yeast showed over-proofing. As such, the company’s T-Control 10.25 products enable consistent quality of freshly baked bread all day long.

Minimised waste, energy savings and improved production processes are also applicable across a range of products including tin bread, pizza bases, speciality breads and more, reveals Semiao.

While the idea of taking small steps to achieve big gains might not be new, these can add up to momentous achievements. For Brailsford, British Cycling was transformed from an also-ran to gaining multiple Olympic gold medals. For British bakers, one marginal gain could be key to unlocking a series of positive transformations.

To discover more about Lesaffre’s T-Control 10.25 products, click here.