Amid a difficult financial climate, Multivac’s dough processing division at Fritsch shows how UK bakers can maximise efficiencies and why digitalisation is important to establishing a competitive future.

In the current climate of food inflation and a cost of living crisis, the UK’s bakery manufacturers, as with all food processors, are facing a number of challenges that are increasing the pressure for them to operate efficiently,sustainably and profitably.

Brexit and the lack of a cheaper source of labour in the market, coupled with ingredient scarcity or soaring costs, are making it difficult to meet increased demand in bakery sectors that are continuing to rise. Meanwhile, consumers are having to cut back on spending to economise as financial stresses on household outgoings, including energy price rises, continue to take their toll.

“What every category in food production is going to be looking at is ‘how do we try to protect the consumer from the rapid inflation that’s coming?’,” says Multivac UK’s sales manager Henry Brook. “Just as one example in the baking industry: flour prices have shot through the roof, largely because of the war in Ukraine, which is a big supplier.

“The industry needs efficiency improvements to help manage these cost increases. However, in doing so and while potentially looking to make savings on ingredients, they also need to protect their product quality and brand reputation.”

Different consumer-driven trends in the market are also bringing their weight to bear on the baking industry. Clear growth in the market for savoury pastries1, for example, and the rise in plant-based products, with the advent of creative new vegetable ingredients, bring with them the challenges of increased production volumes. Yet with limited labour availability, the need to automate processes is more vital than ever before.

“With the rising cost of labour, moving from a manual production process to an automated one often means a saving of several hundred thousand pounds a year,” says Brook. “And we’re commonly seeing paybacks in 12-24 months, and sometimes less. “For example; one automatic tray-loading system can payback in less than six months.”

Within the flourishing savoury pastry category, Brook has observed rapid growth in the plant-based segment. “While it still represents a small part of the category, it’s a big growth area and, if it continues to carry on growing at its current rate, it’s only going to occupy a bigger and bigger space on the shelf,” he notes. However, this brings its own set of challenges, as bakers need to maintain segregation between meat-based and plant-based products, but may not yet have the plant-based production volume to invest in completely separate equipment.

Amid all of this, bakers are aware of the need to stay on top of automation trends to compete effectively in a market where digitalisation and sustainability will play an increasingly important role, but will also help to create efficiency savings and reduction in unnecessary waste, with producers able to really home in on downtime, waste and other processing problems in real time.

According to Brook, the larger players in the market are making the biggest strides towards streamlining their operations, but the mid-sized industrial bakeries are also having to look at ways to save money, as they need to remain competitive in their section of the market.

Yet even for the smaller, artisan bakeries, automating processes such as dough sheet production can offer an advantage. “The bigger the bakery, naturally the more there is to save – and usually, the more capital they have available to make large investments. So it cascades down through the industry in terms of automation and labour saving.”

Complete solutions

To help bakeries address some of these issues, Multivac and the Fritsch business have been working closely to create solutions to help UK companies overcome current challenges – particularly at a semi-industrial and industrial level – and future-proof their businesses.

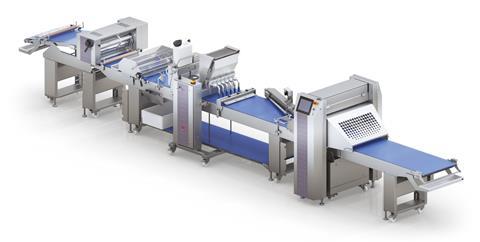

Brook reveals that there has been a real interest in the semi-industrial equipment that Fritsch, now a 96-year-old bakery specialist, has relaunched, such as its Varioflex and Multiflex lines. “These are commonly fed from spools that are created on one of our Rollfix semi-automatic sheeting machines, aimed at customers wanting mid-level output but with maximum flexibility,” he says. “We can produce virtually any sheet pastry product in any shape – for example, coiled, folded, rolled-in – with different decorations on, with greater flexibility than larger industrial lines that are directly fed from an automatic dough sheeter.”

The advantage of this type of line is that it can be deployed quickly into a small footprint to produce a large range of products in an agile production environment, he says. For example, it is ideal for processors wanting to step into the plant-based space, but equally wishing to maintain a separation between the equipment used for plant-based and meat-based pastry products.

At one end, machines will generally require a filling system, and with Multivac UK’s exclusive partnership with Risco, the business can also offer vacuum fillers for a range of products and integrate these into a turnkey solution. In addition, the company has all the processing equipment needed to produce the filling in the first place, including mixers, bowl choppers, grinders and vacuum fillers.

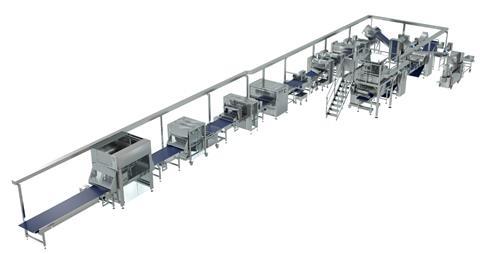

At the other end of the line, the labour-intensive process of putting products on trays by hand can be automated with tray-loading devices. “For the bigger producer, the real solution is to put the whole process inline, from laminator or dough sheeter to the make-up section and into the oven – and after that into the cooler as required,” he says.

For the larger industrial processors, the company offers the Impressa range of machines, which are fed directly from a dough sheeter or U-shaped laminator for high volume production. “After the product is created at the make-up section, it is often fed directly into a travelling oven for baking in a continuous production process, as opposed to batch production,” notes Brook.

As such, Multivac’s UK project team, working in conjunction with Fritsch, are dedicated to bringing complete lines to life and delivering them as a one-stop shop, even integrating with third-party equipment such as ovens, with preferred partners where needed.

While no such line exists in the UK yet, adds Brook, the portfolio of equipment now available to Multivac via its dough processing solutions from Fritsch makes it possible to deliver a production line that continuously produces sausage rolls, for example, from raw ingredients, with no requirement ever to stop (except for maintenance). In this scenario, the sausage meat is produced in a continuous system and brought seamlessly to the filling station at the make-up section for the pastry line, where the laminator provides a never-ending sheet of layered pastry and both are married together to create the final product prior to baking. “We have already delivered solutions in the UK for continuous sausage meat production with our partner Laska. And the layered pastry with one of Fritsch’s industrial laminators is well proven, so it’s not a huge leap of the imagination to bring the two together into one.

“Fritsch excels in industrial bakery lines, producing tens of thousands of products an hour and Multivac is seeking to bring these lines to life and deliver them as a one-stop shop to UK bakeries, even integrating with third-party suppliers to create a continuous production line,” he says.

At Fritsch’s World of Bakery in Kitzingen, Germany, the company welcomes NPD teams to look at the company’s machinery in operation and work with it on process or recipe optimisation, including reducing sugar, fat and other additives, notes Brook. UK bakers can also gain insight on products proving successful in the European market and perhaps gain ideas for the UK’s baking industry. With nearly 100 years’ experience under its belt, the Fritsch team has plenty to offer the UK’s bakers, he concludes.

‘Smart Production Insights’

At Fritsch’s World of Bakery, the company is now focusing on what it calls ‘Smart Production Insights’ (SPI) with the aim of achieving zero downtime in bakery production, reveals Moritz Rahmann, strategic product manager at Fritsch.

This involves the introduction of a real time dashboard, where the operations manager can see the status of a whole production line on their desktop computer, with the ability to analyse how many items are being produced and what products have been received on the line, with all the relevant data stored in the Cloud. If there has been any downtime, it can also reveal why and/or why a line did not produce the required number of pastries produced in an hour, a shift or a day, for example.

In addition, it can give an insight on any technical or service issues with a machine – for example looking at the motor function and alerting the user if a motor is at critical heat level, thus allowing the operator to plan downtime and replace it rather than having to do so in the middle of a production run, which could cost a bakery tens of thousands of pounds in lost production and spoiled product.

While Fritsch’s dashboard approach is not yet in use in the UK, it is already being utilised in German bakeries and is in constant evolution. Fritsch is working closely with the team at Multivac to integrate services and develop a digital portfolio.

As Multivac UK’s Brook points out, these minor efficiency savings are a big money saver for larger bakeries. “When you are talking about industrial lines that produce 50,000 products an hour, unplanned downtime, micro-stoppages and spoiled product are a major cost. So we are looking to eliminate unplanned downtime entirely on our next generation of digital industrial lines, offering a more profitable and sustainable operation to our customers.

“Truly intelligent and sustainable production is where we think the industry is going to go and we’re already taking steps towards it.”

To look at the Varioflex M700 in action, see the video below:

For more information on the equipment both Multivac and Fritsch have to offer, contact henry.brook@multivac.co.uk

Source

1 https://tinyurl.com/2p99c8x8