New machinery from bakery equipment suppliers are set to form highlights of this week’s IBA 2023 in Munich.

We’ve compiled a round-up of the latest innovations on display from 22 to 26 October at the major trade fair, which is making its return from a two-year hiatus due to the pandemic:

Sustainable Oven Solutions, AMF

Bakeries looking to reduce their carbon footprints can check out the AMF exhibition this year. It features the likes of the AMF Den Boer Multibake Vita tunnel oven, powered by the company’s patented hydrogen burners which only emit water as a by-product. Available in several configurations, the system includes grids for sheet pans, mesh belts, and stone plates for pizzas, flatbreads and a wide variety of other products.

Bakers may instead wish to switch to electric ovens, which are said to enable superior process control, higher energy efficiency, and more consistent results, according to AMF. The modular oven system can have steam units added where necessary, while multiple heating chambers help optimise product baking curves. AMF also offers hybrid combinations that can be retrofitted to existing ovens.

AMF said further gas and energy savings can be achieved via the AMF Sustainable Oven Service, which will be demonstrated live at IBA 2023. This combines AI, advanced sensors and cloud computing to monitor temperature, airflow, occupancy, and energy consumption of ovens in real time and provide process optimisation recommendations.

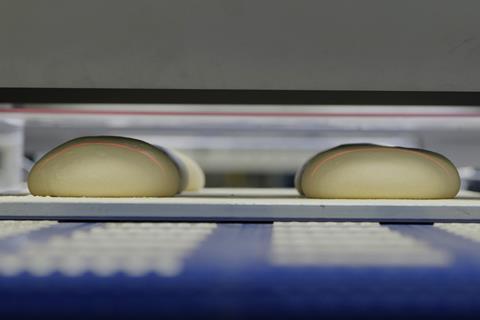

Bread Roll Line and Scoring System, Koenig

Continuing recent developments of its Easy Clean series, Koenig is debuting its KGV EC bread roll line, which it describes as “one of the most powerful units available on the market in the field of simplified cleaning and accessibility”. Its design helps minimise the downtime between production line runs and ensures optimised hygiene without the build up of dough or flour. It can be used to create products ranging from burger rolls, dinner rolls, and stamped rolls, to rose rolls, pretzel rolls, cut rolls, and convoluted rolls, with configurations for other items also possible. Available in various working widths, it can produce up to 36,000 pieces per hour.

Koenig is also giving daily demos in Munich of its new Iscore bread scoring system, said to use sophisticated technology to simulate and even improve the decorative cutting skills of a master baker. Each robot is capable of scoring up to 12,000 times per hour, and each machine can incorporate rotary blades, water-jet tools and ultrasonic knives at the same time. The system can also scan products in 3D so that user-defined scoring patterns can be automatically adapted according to its specific length, width and height. AI monitoring helps maintain high operational standards too.

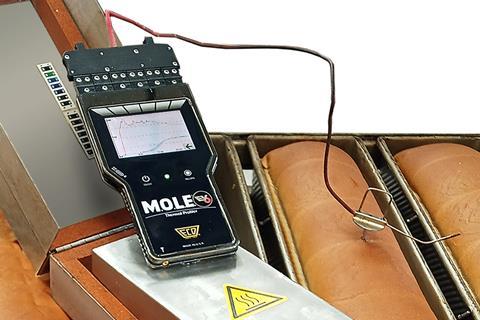

Thermal Profiler, ECD

Thermal profiling of baked goods and verifying oven performance are key to ensuring product quality and consistency, and optimisation of shelf-life and yield. The handheld M.O.L.E. EV6 is said to set a new benchmark for thermal data loggers, with its full colour touchscreen display delivering intuitive control and instantaneous data access, including of S-Curve milestones. The M.O.L.E. platform is the data capture engine for ECD’s portfolio of sensors including BreadOmeter, CakeOmeter, and OvenBalancer, which will all be shown in action at IBA 2023.

Eddie the Edible Ink Printer, Primera

Billed as the world’s first GMP and NSF-certified food printer, the affectionately named Eddie is able to print directly onto cookies, doughnuts, macarons and many other confections, and requires no hand piping, frosting sheets, or drying time, according to Primera.

The machine is capable of printing one complete product design, such as a full-colour photograph or graphic and text, every 10 seconds at an approximate cost of 5p per average-sized cookie. Its rotating carousel tray holds up to 12 items with a maximum width of 110mm each, while a manual feeder can be used to print uniquely shaped products one at a time. A new platform kit also allows printing for goods over 50mm tall, such as doughnuts and mini cakes.

Artisan Sheeted Bread Line, AMF

The new integrated system, developed following extensive research by AMF Tromp, features major upgrades that are designed to simplify maintenance, optimise process control, and reduce energy and water consumption, all the while delivering artisan-style results at high speed. Control of processes from mixing to de-panning have been improved, with the line capable of handling 4,000kg of dough per hour including speciality and high-moisture doughs.

AMF Tromp’s patented flour applicator adds flour to the sides of the dough sheet, thus eliminating the need for oil on the production line. The simplified modular design and ‘toolless sanitation’ affords fast changeovers, and the dough centring unit ensures minimal trimming, with AI also enhancing product accuracy to further reduce waste.

Scoring Tool and Vision System, ABI

The next-generation model of ABI’s Katana robot scoring system is equipped with a waterjet tool, delivering even more flexibility and expanding on features including its ultrasonic plunge and drag blade options. The system enables precision scoring of a wide range of soft bakery products and crusty breads, guaranteeing quality and homogeneity.

Also being exhibited is ABI’s new Eye-Q High Speed Vision System, which drives improved quality control throughout the production line thanks to precise data classification. It can quickly identify the source of defects so production issues can be resolved more efficiently and effectively.

No comments yet